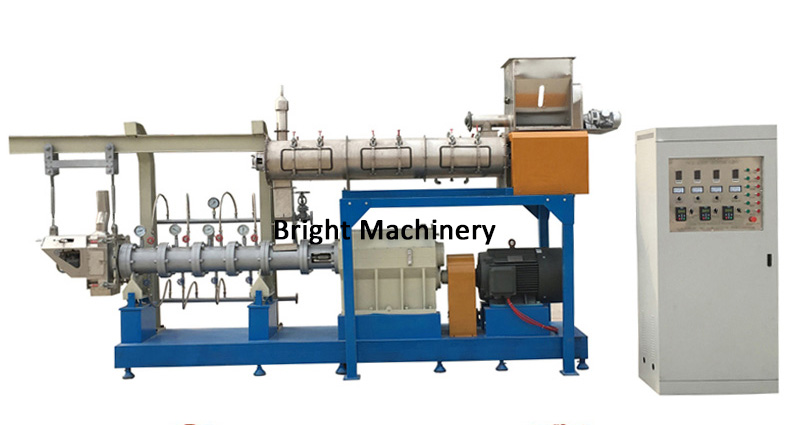

floating fish feed pellet machine production line

floating fish feed pellet machine production line

Fish feed production process: crushing of raw materials →preparation of raw materials (corn meal, soybean meal, starch, fish meal, etc.) →mixer →conveyor →twin screw feed extruder→ hoister→ dryer(electric oven, gas fuel oven or steam oven) →oil sprayer→single roller flavoring line→ cooling conveyor →screening silo→Packing Machine

Fish feed production line can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, turtle, bullfrog and other aquatic feed particles. Fish feed size range: 1 mm, 1.5 mm, 2.0 mm-10 mm.

Fish feed twin-screw extruder: The starch structure of raw materials changes under high temperature and high pressure environment and twin-screw extrusion. It becomes easily absorbed nutrients. It is extruded through feed mould, and the rotating speed of the rotary cutting motor is adjusted until the feed particles of the same size are adjusted. Particle size and shape are obtained by replacing the die. Feed puffing machine adopts advanced frequency conversion speed control technology, more energy-saving, more accurate speed control, motor running current, speed can be directly seen through the converter panel, to ensure the safety of equipment.

компания :

Адрес :

Телефон :

почтовый ящик :

Skype :

Whatapp/Wechat: